Our Application Solution

Panamich electronic is a manufacturer of innovative display touch system solutions for customers all over the world. The company has many years of experience in touch Screen and LCDmodule design and manufacturing team. With excellent operation mode of in-depth technology development and designintegration, Panamich electronics provides a full range of touch display technology solutions.

We will continue to develop advanced touch Screen and integration technologies, lay out the thinnest and narrowest borders, giant size and 3D appearance technologies in the industry, and integrate the touch display solutions with the most complete technical level and service in the industry.............

Our Product

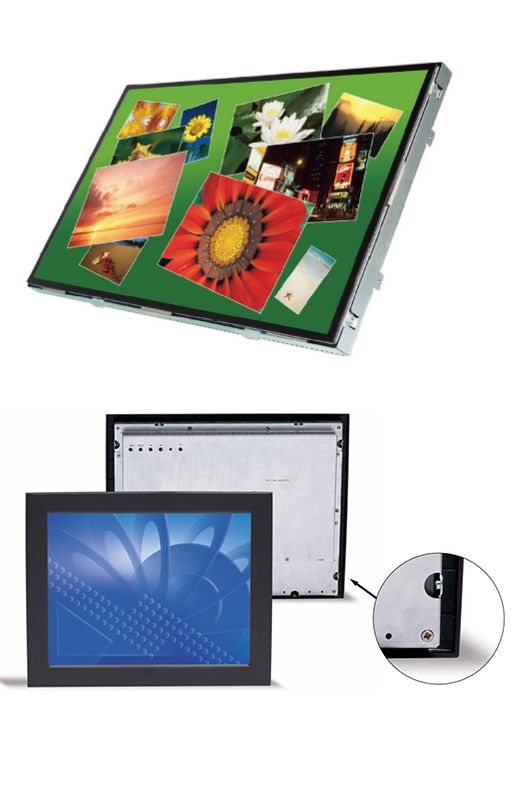

Touch Screen Systems

Our PCAP touch screen sizes range from 5 “to 65”, and we can also provide customized solutions according to customer needs.

Introducing a more durable, scalable and easy-to-integrate multi-touch system that stands up to rugged industrial environments, makes retail brand experiences more robust and makes public exhibits more interactive. The projected capacitive (PCAP) multi-touch systems deliver. Ideal for small format multi-touch display applications, this system offers display integrators and equipment manufacturers a reliable, easy-to-integrate multi-touch system with no bulky bezels. The system’s glass-to-edge design delivers the same modern design aesthetic users have come to expect from today’s personal smart phones and tablets.

Touch Display

More than 5-20 touch input points.Supports multiple installation methods, wall mounted and embedded.Supports working environment temperatures ranging from -20 ° C to 60 ° C.Support glove touch input. (Medical gloves, conductive gloves)

- Size: 7"-32"

- Surface capacitive touch screen

- Resistive touch screen

- PCAP Multi touch Screen

- Supports working environment temperatures ranging from -20 ° C to 60 ° C

- Supported OS: Android, Windows, Linux, Mac,NeoKylin

•Using Projection Capacitive Screen Technology (PCAP); •Ultra-fast 5 ms touch response for quick interactions; •Anti-stiction surface enhances the user experience; •Provides 91% light transmission.

Touch Screen Kiosk

Our PCAP touch screen sizes range from 5 “to 65”, and we can also provide customized solutions according to customer needs.

Introducing a more durable, scalable and easy-to-integrate multi-touch system that stands up to rugged industrial environments, makes retail brand experiences more robust and makes public exhibits more interactive. The projected capacitive (PCAP) multi-touch systems deliver. Ideal for small format multi-touch display applications, this system offers display integrators and equipment manufacturers a reliable, easy-to-integrate multi-touch system with no bulky bezels. The system’s glass-to-edge design delivers the same modern design aesthetic users have come to expect from today’s personal smart phones and tablets.

Why choose us

Technology & Services

We have many years of manufacturing experience and technology, which are sold to various countries and regions around the world.. Besides, we guarantee that you will be satisfied with our customer service.

Learn More About Us

Availability

Our products are available worldwide thanks to our shipping & delivery partners who offer:

- 24/7 delivery services

- Qualified consultations

- Any necessary support

Showcase